Enabling cost-effective carbon capture technology to industrial emitters at gigatonne scale.

Tags

Steel Manufacturing

Carbon Capture Technology (CCT)

Emissions Reduction

Cost-Effective Sustainability

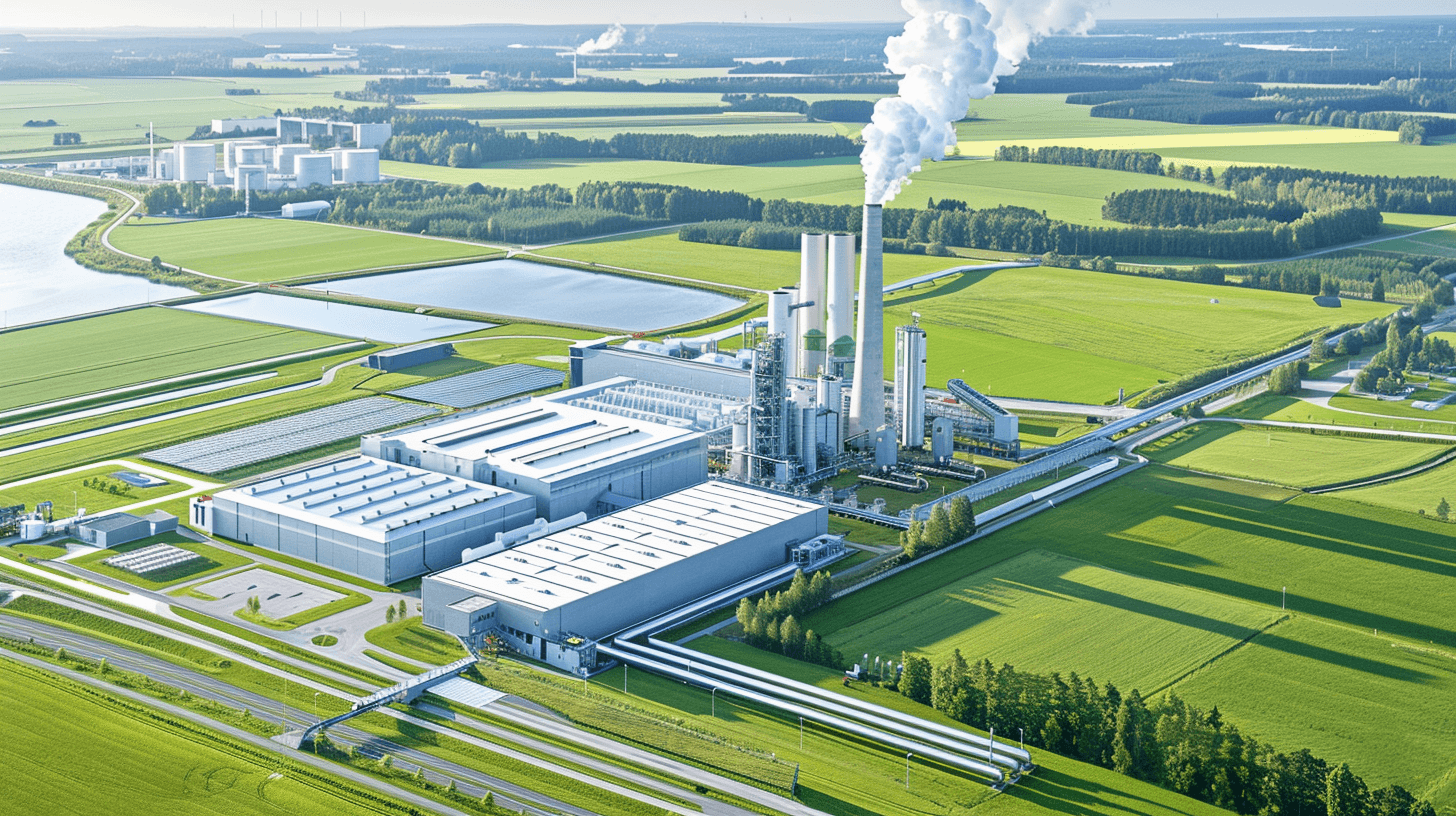

This case study explores ClimaCo's successful collaboration with Acme Steel, a leading steel manufacturer, to implement a groundbreaking carbon capture technology (CCT) solution. Facing mounting pressure to reduce their environmental footprint,

About Acme Steel

Acme Steel is a global leader in the steel manufacturing industry, renowned for its high-quality products and commitment to innovation. However, steel production generates significant CO2 emissions, a leading contributor to climate change. Recognizing the need for environmental responsibility and aligning with stricter regulations, Acme Steel sought a sustainable solution to minimize their environmental impact.

Challenge

Acme Steel faced a multi-faceted challenge:

Large-Scale Capture: Their steel mills produced vast quantities of CO2 emissions, requiring a CCT solution capable of capturing emissions at a gigatonne scale (one billion metric tons).

Cost-Effectiveness: Existing CCT solutions can be prohibitively expensive. Acme Steel needed a cost-efficient approach to ensure the long-term sustainability of their efforts.

Integration Challenges: Integrating a new CCT system into their existing infrastructure without disrupting production was crucial.

Solution

ClimaCo partnered with Acme Steel to implement a customized CCT solution tailored to their specific needs. The solution included:

Advanced Capture Technology: ClimaCo's cutting-edge CCT system utilizes chemical absorption technology to efficiently capture CO2 directly from the emissions stream. This involves using a special solvent that absorbs CO2, allowing it to be separated from the other gases in the emissions stream.

Scalable Design: The system was designed with scalability in mind, allowing Acme Steel to capture vast quantities of CO2 emissions across multiple production facilities without sacrificing efficiency.

Cost-Optimized Approach: ClimaCo focused on optimizing the system's design and operational processes to ensure long-term cost-effectiveness. This included factors such as maximizing solvent reuse and minimizing energy consumption.

Seamless Integration: ClimaCo's team worked closely with Acme Steel's engineers to ensure a smooth integration of the CCT system into their existing infrastructure, minimizing disruption to daily operations.

Results & benefits

The implementation of ClimaCo's CCT solution yielded significant positive results for Acme Steel:

Gigatonne-Scale Capture: The system successfully captured CO2 emissions at a gigatonne scale, substantially reducing Acme Steel's overall environmental footprint. This significant reduction in emissions represents a major step forward in their commitment to sustainability.

Cost-Effective Sustainability: The optimized design and operational processes minimized the long-term costs associated with carbon capture, ensuring the financial viability of the solution for Acme Steel.

Enhanced Brand Reputation: By actively addressing climate change concerns, Acme Steel solidified their position as a leader in environmental responsibility, boosting their brand reputation and attracting environmentally conscious customers.